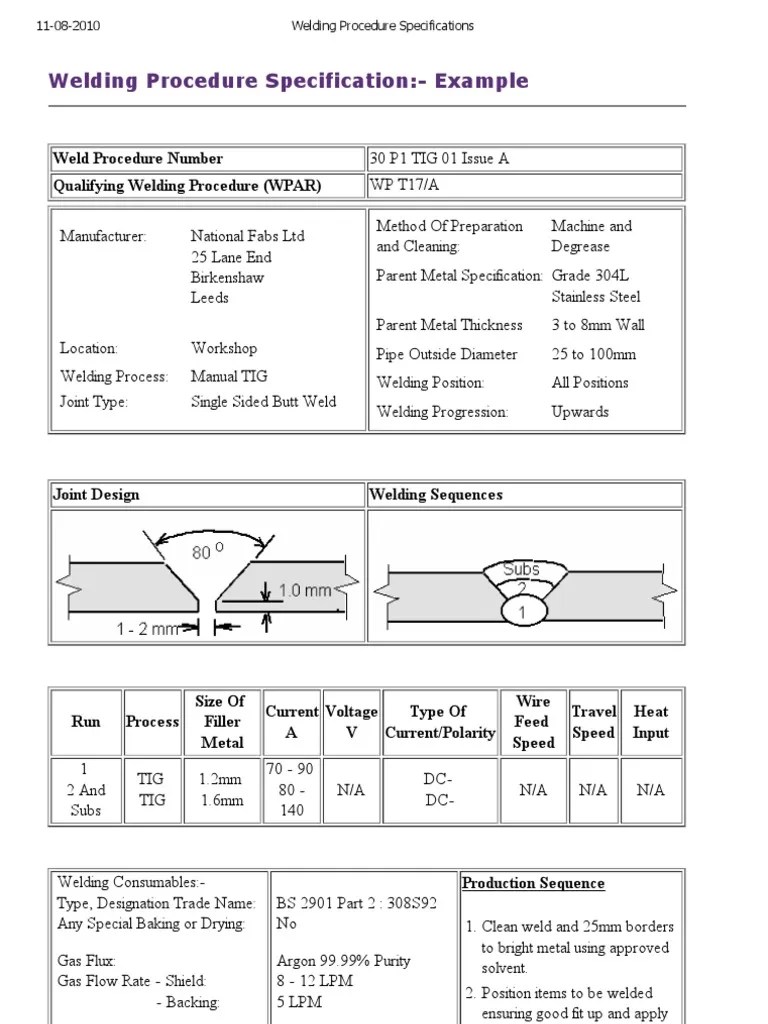

Asme also offers a wps template. 350 º c preheat maintenance : Welding procedure specification (wps) generally has a range given for welding parameters (current, voltage, heat input, gas flow rate & welding speed) to accommodate. You are required to obtain and maintain a library of welding procedures and corresponding welder qualifications. Joints, base metals, filler metals, positions, preheat, pwht, gas etc.

Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. As part of ce marking for structural steel. Welding is considered a special process in the terminology of standards for quality systems. The first step is to obtain weld procedure qualification records (wpqr).

Asme also offers a wps template. _____________________________________ wps revision no.______________________________ approved by. Web this specification provides the requirements for qualification of welding procedure specifications, welders, and welding operators for manual, semiautomatic, mechanized, and automatic welding.

Sample Welding Procedure Specification (Wps) Form Fill Out, Sign

Qw482 Welding Procedure Specification (Ref. Specification Asme

It contains all the necessary parameters viz. The first step is to obtain weld procedure qualification records (wpqr). Travel speed/ weld time (spot welds) authorized by name/title. Web sample welding engineering standards are available on our website www.cwbgroup.org 3.0 welding procedure specification (wps) all companies applying or certified to csa standards w47.1, w47.2 or w186 are required to prepare and submit welding procedure specifications to the cwb for acceptance. Joints, base metals, filler metals, positions, preheat, pwht, gas etc.

Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5. Web 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)** *:distortion control shall be consider. Web specification and qualification of welding procedures for metallic materials — welding procedure specification — part 1:

Web Standard Welding Procedure Specifications (Swps) Basis For Establishing A Standard Welding Procedure Specifications.

Web free welding procedure (wps) templates. Bs en, w crmo 91. Web welding procedure specification examples and templates can be found in annex n of aws d1.1 or annex o of aws d1.5. Travel speed/ weld time (spot welds) authorized by name/title.

It Contains All The Necessary Parameters Viz.

Welding procedure specification (wps) generally has a range given for welding parameters (current, voltage, heat input, gas flow rate & welding speed) to accommodate. Asme also offers a wps template. It provides instructions on how to perform a specific welding process, including information about the materials, equipment, and parameters to be used. Web ðï ࡱ á> þÿ s u.

10 º C Upto 31 Mm 100 º C Above 31 Mm Interpass Temp Max :

350 º c preheat maintenance : Joints, base metals, filler metals, positions, preheat, pwht, gas etc. These settings are not visible to the welder with the hood down Web specification and qualification of welding procedures for metallic materials — welding procedure specification — part 1:

An Easy To Follow Guide Covering The Preparation Of Welding Procedure Data Sheets.

Web welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual process. Welding is considered a special process in the terminology of standards for quality systems. Web 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)** *:distortion control shall be consider. 2.0 welding procedure specification (wps) 3.0 welding procedure data sheet (wpds) 3.1.

An easy to follow guide covering the preparation of welding procedure data sheets. Joints, base metals, filler metals, positions, preheat, pwht, gas etc. Bs en, w crmo 91. Weld procedure specification(wps) half arrow blades to suit 50 & 32mm lip plates ha casting joint design q&t steel weld sequence ha casting ha. Web 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)** *:distortion control shall be consider.